Kaluwihan

Resistance oksidasi suhu dhuwur

Ketahanan korosi sing apik banget

resistance abrasion apik

Koefisien konduktivitas panas sing dhuwur

Self-lubricity, Kapadhetan kurang

kekerasan dhuwur

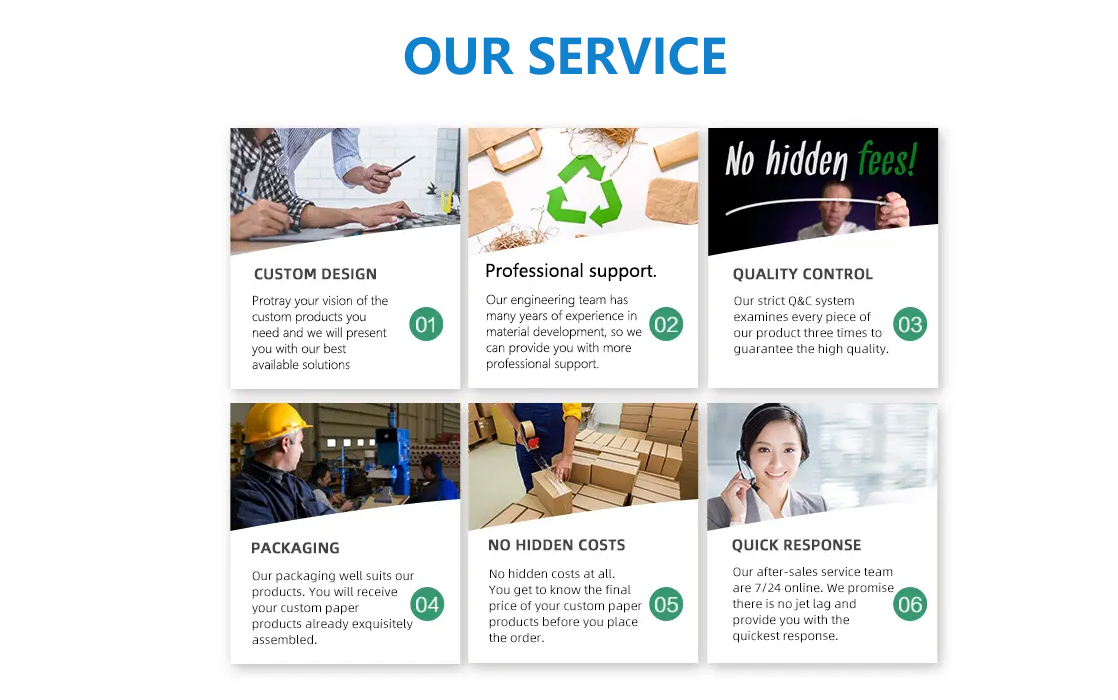

Desain sing disesuaikan.

Aplikasi

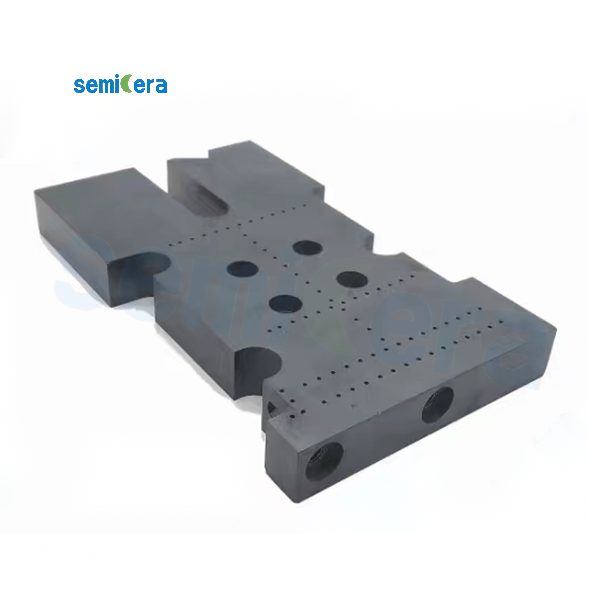

-Lapangan tahan aus: bushing, piring, nozzle sandblasting, lapisan siklon, laras penggilingan, lsp...

-Bidang Suhu Dhuwur: siC Slab, Quenching Tube Tube, Radiant Tube, Crucible, Elemen Pemanas, Roller, Beam, Heat Exchanger, Pipa Udara Dingin, Burner Nozzle, Thermocouple Protection Tube, SiC boat, Kiln Car Structure, Setter, etc.

-Silicon Carbide Semiconductor: SiC wafer boat, sic chuck, sic paddle, sic cassette, sic diffusion tube, wafer fork, suction plate, guideway, etc.

-Silicon Carbide Seal Field: kabeh jinis ring sealing, bantalan, bushing, etc.

-Photovoltaic Field: Cantilever Paddle, Grinding Barrel, Silicon Carbide Roller, etc.

- Lapangan Baterei Lithium

Sifat Fisik SiC

| Properti | Nilai | Metode |

| Kapadhetan | 3,21 g/cc | Sink-float lan dimensi |

| Panas spesifik | 0,66 J/g °K | Lampu kilat laser pulsa |

| Kekuatan lentur | 450 MPa 560 MPa | 4 titik tikungan, RT4 titik tikungan, 1300° |

| Ketangguhan fraktur | 2,94 MPa m1/2 | Microindentation |

| Kekerasan | 2800 | Vicker's, 500g ngemot |

| Modulus Elastis Modulus Muda | 450 GPa430 GPa | 4 pt bend, RT4 pt bend, 1300 °C |

| Ukuran gandum | 2 – 10 µm | SEM |

Sifat termal SiC

| Konduktivitas termal | 250 W/m °K | Metode lampu kilat laser, RT |

| Thermal Expansion (CTE) | 4,5 x 10-6 °K | Suhu kamar nganti 950 ° C, silika dilatometer |

Parameter teknis

| Item | Unit | data | ||||

| RBSiC (SiSiC) | NBSiC | SSiC | RSiC | OSiC | ||

| konten SiC | % | 85 | 75 | 99 | 99.9 | ≥99 |

| Konten silikon gratis | % | 15 | 0 | 0 | 0 | 0 |

| Suhu layanan maksimal | ℃ | 1380 | 1450 | 1650 | 1620 | 1400 |

| Kapadhetan | g/cm3 | 3.02 | 2.75-2.85 | 3.08-3.16 | 2.65-2.75 | 2.75-2.85 |

| Porositas mbukak | % | 0 | 13-15 | 0 | 15-18 | 7-8 |

| Kekuwatan mlengkung 20 ℃ | Mbak | 250 | 160 | 380 | 100 | / |

| Kekuwatan mlengkung 1200 ℃ | Mbak | 280 | 180 | 400 | 120 | / |

| Modulus elastisitas 20 ℃ | Gpa | 330 | 580 | 420 | 240 | / |

| Modulus elastisitas 1200 ℃ | Gpa | 300 | / | / | 200 | / |

| Konduktivitas termal 1200 ℃ | W/mK | 45 | 19.6 | 100-120 | 36.6 | / |

| Koefisien ekspansi termal | K-1X10-6 | 4.5 | 4.7 | 4.1 | 4.69 | / |

| HV | Kg/mm2 | 2115 | / | 2800 | / | / |

Lapisan karbida silikon CVD ing permukaan njaba produk keramik karbida silikon recrystallized bisa nggayuh kemurnian luwih saka 99.9999% kanggo nyukupi kabutuhan pelanggan ing industri semikonduktor.